Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

304 North Cardinal St.

Dorchester Center, MA 02124

:400300.jpg)

:400300-1024x768.jpg)

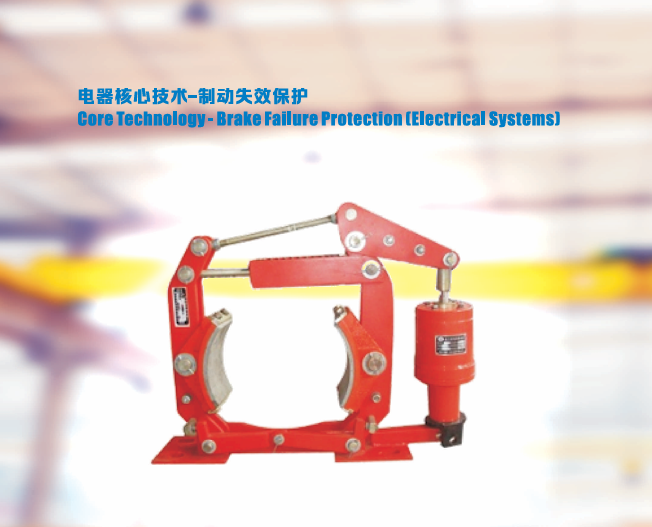

In the realm of industrial lifting operations, where precision meets power, safety stands as the non-negotiable cornerstone of every successful mission. Our pioneering Brake Failure Protection Technology redefines crane safety through intelligent electrical control systems that respond to emergencies with unparalleled reliability. This technology represents the convergence of sophisticated engineering and practical safety solutions, offering comprehensive protection when it matters most.

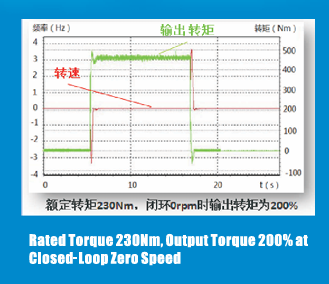

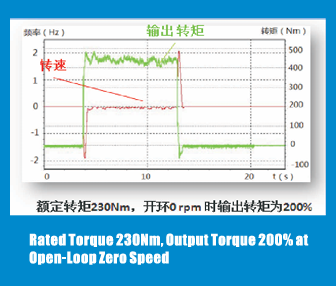

The system operates on a brilliantly engineered principle: when brake failure occurs and an uncontrolled descent begins, our frequency converter immediately commands the motor to generate sufficient torque to safely arrest the falling load. This crucial intervention transforms a potential disaster into a controlled safety event, demonstrating our commitment to crane operational safety and load security. What makes this system truly remarkable is its compatibility with both closed-loop and open-loop vector control configurations, providing flexible implementation across diverse crane systems while maintaining emergency response reliability.

Real-world applications demonstrate this technology’s vital importance. In steel manufacturing plants, where overhead cranes transport multi-ton ladles of molten metal, a brake failure without this protection could lead to catastrophic spills endangering both personnel and infrastructure. Port operations handling container ships face similar risks—uncontrolled descending containers could cause devastating collisions with vessels or dock structures. Wind energy projects, where turbine components are lifted to dizzying heights, depend entirely on failsafe braking systems to protect both workers and multimillion-dollar equipment. Even in manufacturing facilities, where precision placement of heavy machinery is routine, this technology prevents costly accidents and production disruptions.

The performance foundation of our system rests on proven engineering excellence. Both control modes enable zero-speed suspension with 200% rated torque output, providing substantial safety margins that exceed standard industry requirements. This robust capability ensures reliable load holding even in the most challenging conditions, supporting overhead crane safety and industrial lifting security. The technology’s adaptability across different control methodologies makes it suitable for various applications, from construction crane operations to mining equipment handling and logistics center material flow.

What truly sets our system apart is its integrated operator guidance functionality. When activated, the system provides clear voice alerts that direct operators to safely lower the suspended load to a secure position. This thoughtful feature combines automated safety protocols with human-centered design, ensuring not only immediate danger mitigation but also facilitating subsequent brake maintenance procedures. This comprehensive approach addresses the entire safety continuum—from emergency response to system recovery.

Without this advanced protection, industries face significant vulnerabilities. Crane maintenance costs escalate due to unpredictable failure patterns. Operational downtime increases as safety concerns force more conservative working methods. Insurance premiums rise with higher risk assessments, while regulatory compliance becomes more challenging to maintain. Most importantly, personnel safety remains constantly at risk, with the potential for load drop incidents always present in operations relying solely on conventional braking systems.

Our technology directly addresses these concerns through multiple protective layers. The system’s real-time monitoring capabilities continuously assess brake performance, while its predictive safety algorithms can identify deteriorating conditions before complete failure occurs. When intervention becomes necessary, automated torque control engages seamlessly, providing that critical bridge between system failure and safe resolution. This comprehensive approach supports preventive maintenance strategies while ensuring continuous operational safety.

The implementation of this technology brings transformative benefits to material handling operations. Heavy industry manufacturers gain enhanced confidence in their lifting processes. Infrastructure developers can proceed with complex projects knowing they have superior safety backups. Port authorities achieve better equipment utilization through reduced downtime and enhanced reliability. Across all sectors, this technology represents not just an added feature, but a fundamental reimagining of how crane safety should be engineered and implemented.