Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

304 North Cardinal St.

Dorchester Center, MA 02124

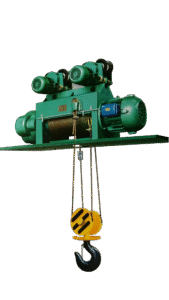

Our factory-direct Metallurgical Electric Hoist is engineered for reliable performance in harsh, high-temperature working conditions, delivering safe and efficient lifting for steel plants, factories, ports, and metro construction projects. Built to industrial standards, this heavy-duty electric hoist is widely used with overhead crane systems and bridge cranes, effectively solving problems such as unstable lifting, frequent downtime, and safety risks in metallurgical operations. We provide complete mechanical drawings and technical documentation to support installation and customization. Designed for durability and continuous operation, it ensures long service life and stable output. Backed by guaranteed after-sales support, each order is followed by a dedicated production specialist, ensuring transparent scheduling, quality control, and on-time delivery from manufacturing to shipment.

The Metallurgical Electric Hoist is designed specifically for steel mills,

foundries,and high-temperature industrial environments.Its reinforced structure allows reliable operation in dusty,

hot,and continuous-duty conditions.Suitable for lifting molten metal ladles,steel billets,and heavy castings,

it integrates seamlessly with overhead cranes,gantry cranes,and other industrial material handling hoist systems.

This high-temperature electric hoist ensures stable performance in demanding applications,

making it ideal for heavy-duty industrial lifting tasks.

High-temperature-resistant construction for safe operation near furnaces and hot metal

Dual braking system for enhanced safety and operational reliability

Heavy-duty wire rope hoist mechanism,suitable as a wire rope hoist for steel mills

Efficient cooling and protective design to prevent motor overheating

Smooth operation with minimal vibration for precise load handling

Compatible with overhead crane metallurgical hoist and gantry crane heavy-duty hoist systems

Lifting Capacity:1–50 Tons

Lifting Height:6–30 m(Customizable)

Lifting Speed:3–8 m/min

Duty Class:M3–M5

Power Supply:380V/50Hz(Customizable)

Control Mode:Pendant or Remote Control

Protection Level:IP54/IP55

High-Temperature Reliability

Designed to withstand extreme heat and maintain consistent lifting performance in metallurgical environments,making it a reliable high-temperature wire rope hoist.

Heavy-Duty And Durable

Reinforced components and robust wire rope ensure long-term operation under harsh conditions.

Versatile Integration

Easily fits overhead,gantry,and single/double-girder crane systems for various metallurgical lifting and industrial material handling hoist needs.

Steel mills and metallurgical workshops

Foundry and casting lines

Molten metal ladle and billet handling

High-temperature material transfer operations

Industrial production lines requiring heavy-duty lifting

Remote installation and commissioning guidance

Online troubleshooting and technical support

Digital manuals and operational training

Long-term spare parts supply

Lifetime technical assistance

1.How Do I Select The Right Metallurgical Electric Hoist For My Facility?

Consider lifting capacity,lifting height,duty cycle,and operating temperature to match the specific metallurgical application and industrial material handling hoist requirements.

2.Can The Metallurgical Electric Hoist Operate In High-Temperature Environments?

Yes,its heat-resistant structure and dual braking system allow stable operation as a high-temperature electric hoist in steel mills and foundries.

3.Is The Metallurgical Electric Hoist Compatible With Existing Crane Systems?

It can be installed on single-girder,double-girder,overhead crane metallurgical hoist,or gantry crane heavy-duty hoist systems,providing flexible integration.

4.What Safety Features Are Included In The Metallurgical Electric Hoist?

It includes dual brakes,overload protection,upper/lower limit switches,and thermal motor protection for safe and reliable operation.

5.How Do I Ensure Long-Term Reliability For The Metallurgical Electric Hoist?

Regular maintenance,adherence to duty cycle guidelines,and proper cooling and lubrication of moving parts help extend service life for industrial material handling hoist operations.