Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

304 North Cardinal St.

Dorchester Center, MA 02124

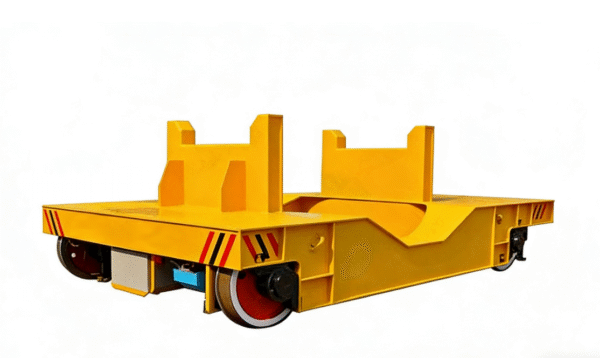

The Ladle Transfer Electric Flat Car is engineered specifically for steel plants,foundries,smelting workshops,and metallurgical lines that require safe,stable,and high-temperature-resistant transport of molten steel ladles.As a factory-direct manufacturer specializing in heavy industrial transfer vehicles,we design each unit with reinforced frames,heat-shielding structures,high-temperature insulation,double-drive motors,and reliable electric control systems—ensuring smooth and secure ladle movement within harsh steelmaking environments.

This electric flat car supports customized load capacity,table size,rail type,speed control,and safety systems,meeting project-level requirements for ladle transfer solutions in casting bays,converter areas,continuous casting sections,ladle furnaces,and refining stations.It fits the global demand for factory-direct ladle transfer cars,OEM metallurgical transport equipment,customized slag/steel ladle carts,and heavy-duty electric rail transfer systems.

Built with heat-resistant steel,thermal insulation layers,and protective shielding to withstand radiant heat from molten steel ladles.

Designed for extreme loads with a strengthened frame,rigid axle sets,and industrial-grade wheels suitable for continuous metallurgical duty cycles.

Features dual-motor drive,VFD-controlled soft start/stop,stable speed adjustment,and high reliability for long-distance travel on rails.

Optional ladle locking devices,temperature-resistant guards,remote monitoring,overspeed protection,and emergency stop functions ensure safe transfer.

Capacity range,table height,rail gauge,pedestal type,insulation grade,and electric control configurations can all be customized to your project.

| Model | Capacity(t) | Table Size(mm) | Rail Gauge(mm) | Speed(m/min) | Drive Mode | Motor Type | Control Mode | Safety Options |

| LTC-50 | 50 | 3000×2500 | 1435/Custom | 0–20 | Electric Drive | AC Motor+VFD | Pendant+Remote | Heat Shield/Lock Device |

| LTC-80 | 80 | 3500×2600 | 1435/Custom | 0–18 | Electric Drive | AC Motor+VFD | Remote/Cabin | Fireproof Panels |

| LTC-100 | 100 | 3800×3000 | 1435/Custom | 0–15 | Double Drive | High-Temp Motor | Remote/PLC | Overspeed Protection |

| LTC-150 | 150 | 4200×3200 | 1435/Custom | 0–12 | Double Drive | AC Heavy-Duty | Remote/Cabin | Temperature Monitoring |

| LTC-Custom | Custom | Custom | Custom | Custom | Custom | Custom | Custom | Custom |

(Custom OEM upgrades:hydraulic lifting deck,ladle cradle,slag-ladle structure,AGV navigation,enhanced heat protection system.)

Steelmaking converters(BOF)

Electric arc furnace(EAF)workshops

Ladle refining furnace stations

Continuous casting machines

Casting bays&metallurgical foundries

Slag handling&molten metal transfer lines

Safely transports molten steel ladles under extreme temperatures

Reduces manual handling risks in metallurgical processes

Ensures smooth and vibration-free movement of ladles along production lines

Supports stable and continuous casting operations

Enhances production safety and efficiency during molten metal handling

Q1:Why choose your factory-direct ladle transfer flat car?

We manufacture the entire system in-house—metal structure,motor drive,electric control—ensuring high reliability,stable quality,and competitive pricing for global buyers.

Q2:Can this equipment handle extreme heat from steel ladles?

Yes,reinforced frames,heat shields,fireproof insulation,and temperature-resistant wiring are included or customizable.

Q3:Do you support long-distance or heavy-duty operation?

Yes,double-drive motors,high torque output,and VFD controllers ensure stable travel over long distances.

Q4:Can the structure be customized for different ladle types?

Yes,OEM cradle arms,locking mechanisms,lifting pedestals,and slag-ladle structures can be added.

Q5:Do you support overseas engineering partners and distributors?

Yes,we supply OEM/ODM,wholesale,distributor,and exporter solutions for global metallurgical projects.

Remote installation and commissioning guidance

Video-based technical support for electrical systems

Factory video tours for structural and quality confirmation

Continuous assistance for motor upgrades,wiring,controls,and safety systems

Long-term OEM spare parts supply for motors,wheels,gearboxes,and electrical components

1.Can the flat car operate continuously in high-temperature zones?

Yes,structural insulation and heat shielding are designed for continuous metallurgical environments.

2.What types of ladles can it transport?

Steel ladles,slag ladles,hot-metal ladles,and customized metallurgical containers.

3.Is automatic control available?

Yes—PLC systems,remote operation,and semi-automatic modes are optional.

4.Can speed be adjusted?

VFD systems allow smooth speed regulation to protect both load and equipment.

5.Do you offer OEM solutions for project-based requirements?

Yes—capacity,dimensions,controls,safety systems,and rail gauges can all be customized.