Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

304 North Cardinal St.

Dorchester Center, MA 02124

In today’s rapidly evolving industrial landscape, efficiency, accuracy, and safety are no longer optional—they are essential. As warehouses, ports, and manufacturing facilities strive to optimize operations, the role of advanced crane systems has come into sharp focus. But what exactly makes a crane system not just functional, but truly intelligent? The answer lies in two core technologies: the Driving Positioning System and the Anti-Rolling System. Together, they form the backbone of what is fast becoming a hot search trend in industrial automation: Precision Crane Automation.

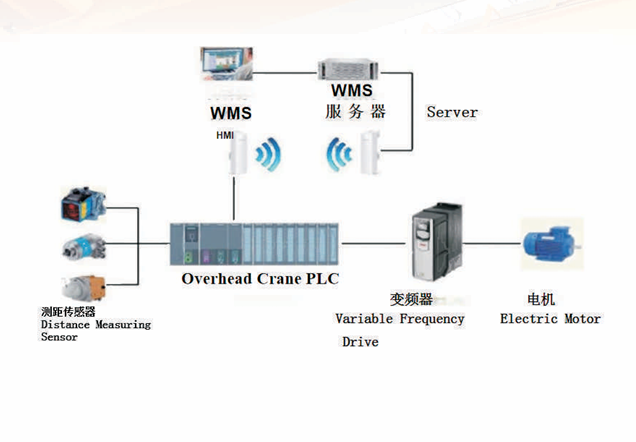

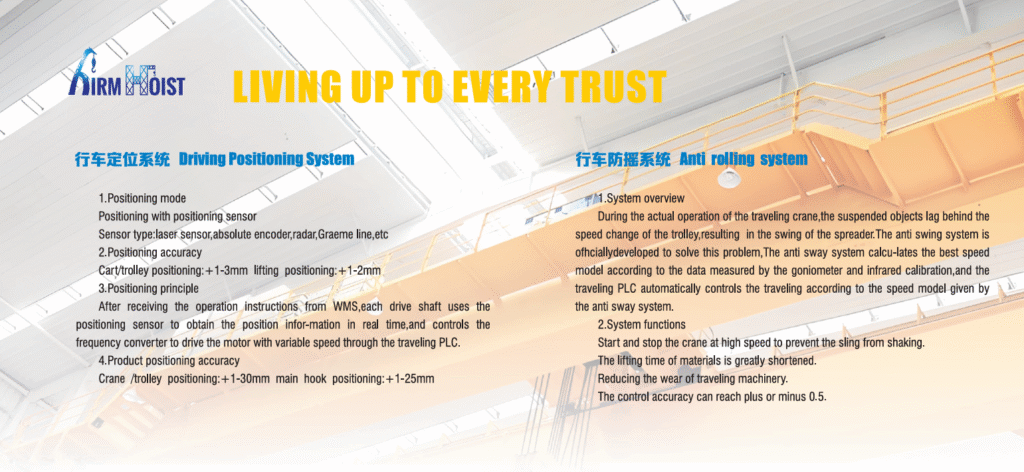

At the heart of any automated crane system is the Driving Positioning System. This technology utilizes sensors such as laser sensors, absolute encoders, radar, and Graeme lines to achieve remarkable positioning accuracy—often within ±1–3mm for crane and trolley movement, and ±1–2mm for lifting operations. How does it work? Once the Warehouse Management System (WMS) issues an operation command, the system’s PLC uses real-time data from these sensors to control the motor via variable frequency drives. This ensures that every movement is not only precise but also seamlessly integrated into the broader automated workflow. For industries where millimeter-level accuracy matters—such as automotive, steel, or logistics—this technology answers the growing search query: “high-accuracy crane positioning solutions.”

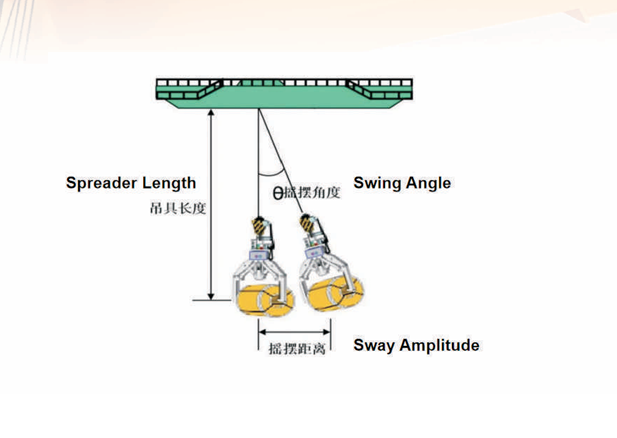

However, precision positioning is only part of the equation. In real-world operations, cranes often face a persistent challenge: load sway. When the trolley accelerates or decelerates, the suspended load tends to swing, causing delays, safety risks, and wear on equipment. This is where the Anti-Rolling System comes into play. By using inclinometers and infrared calibration, the system calculates an optimal speed model and adjusts crane movement in real time to minimize swinging. The result? Faster, smoother, and safer load handling. This capability is increasingly relevant to queries like “crane anti-sway technology” and “how to reduce crane oscillation.”

What sets these systems apart is their synergy. When combined, they enable cranes to operate with unprecedented speed and stability. The anti-sway system not only shortens material handling time but also reduces mechanical wear, while the positioning system ensures that loads are placed exactly where they need to be—every time. This dual-technology approach is especially valuable in high-throughput environments, where even minor inefficiencies can lead to significant downtime or bottlenecks. Could this be why terms like “automated crane control systems” and “smart warehousing technology” are trending among engineers and operations managers?

From a broader perspective, the adoption of such systems reflects a shift toward Industry 4.0, where data-driven automation and real-time feedback are becoming standard. Companies investing in these technologies are not just upgrading equipment—they are future-proofing their operations. Whether it’s achieving ±0.5 control accuracy in anti-sway performance or integrating crane data with ERP and MES platforms, the benefits extend far beyond the warehouse floor. Are businesses truly prepared for this level of operational intelligence?

As industries continue to prioritize automation, safety, and efficiency, the demand for intelligent crane solutions will only grow. Whether you are looking to enhance positioning accuracy, eliminate load sway, or integrate crane operations into a fully automated workflow, these systems offer a proven path forward. They represent not just an improvement, but a transformation—in how materials are moved, how time is used, and how trust is built in industrial environments.

If you are exploring how precision crane automation can elevate your operations, or if you have questions about implementing driving positioning and anti-sway systems in your facility, our team is here to assist. We provide tailored insights and integration support to help you achieve seamless, efficient, and intelligent material handling.

For more detailed information or to discuss your specific needs, feel free to contact us. We are committed to helping you find the right automated solutions for your business.