Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

304 North Cardinal St.

Dorchester Center, MA 02124

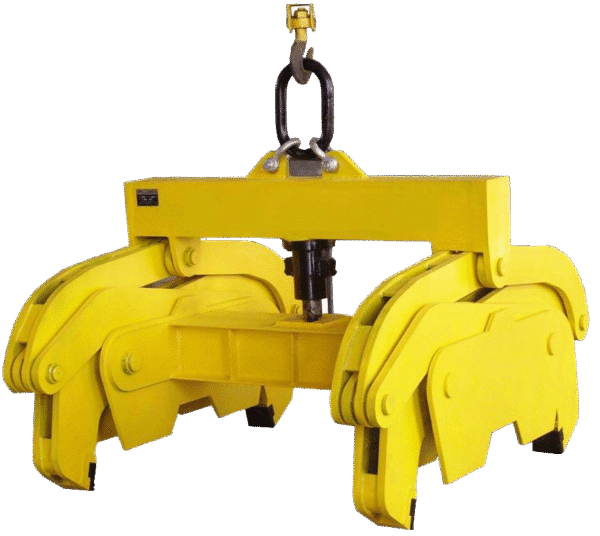

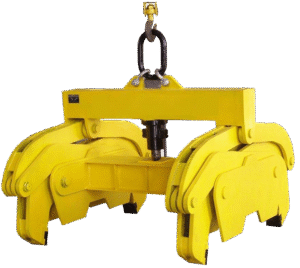

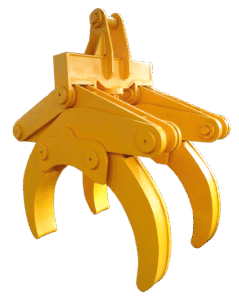

Our Crane Lifting Clamp is a factory-direct lifting solution designed for safe, efficient, and reliable material handling in industrial lifting, steel plate handling, and demanding construction equipment applications. Manufactured with high-strength alloy steel and strict quality inspection, each crane lifting clamp delivers consistent gripping force, excellent wear resistance, and long service life. Complete mechanical drawings and technical specifications can be provided to support system integration and operation planning. The product adapts to a wide range of on-site lifting conditions and effectively solves problems such as unstable loads, inefficient manual handling, and safety risks during vertical or horizontal lifting. With guaranteed after-sales support, professional technical assistance, and dedicated staff tracking production and orders from manufacturing to delivery, we ensure dependable quality, smooth procurement, and long-term operational confidence for customers worldwide.

As a factory-direct crane component manufacturer,we produce high-quality Crane Lifting Clamps engineered for safe,efficient,and reliable handling of steel plates,beams,and other heavy industrial materials.

Designed for overhead cranes,gantry cranes,and hoisting systems,these clamps provide stable gripping,prevent slippage,and protect the workpiece during lifting,loading,or transport operations.

Built with hardened alloy steel jaws,reinforced frames,and precision locking mechanisms,our lifting clamps are suitable for workshops,shipyards,steel mills,construction sites,and fabrication plants.

Available in vertical,horizontal,and universal types,each clamp can be customized to meet specific load capacities,material thicknesses,and global safety standards.

The Crane Lifting Clamp offers secure gripping,smooth operation,and factory-direct reliability.Its hardened gripping surfaces prevent damage to steel plates while maintaining friction for heavy-duty lifting.

Precision-engineered locking mechanisms ensure safe engagement and disengagement,and the reinforced frame supports repeated cycles under rigorous industrial conditions.

Global users searching for lifting clamp supplier,OEM crane clamp manufacturer,factory-direct lifting clamp solution,

or customized heavy-duty clamps will find this model meets international safety and performance standards.

Hardened alloy steel jaws with adjustable pressure ensure secure lifting of steel plates and beams.

Vertical clamps for upright lifting,horizontal clamps for side lifting,and universal clamps for flexible handling.

Reinforced frame,heat-treated jaws,and precision pins deliver long service life and low maintenance.

We offer custom sizes,load capacities,marking,coatings,and mechanical adjustments according to project needs.

Designed for overhead cranes,gantry cranes,hoists,and workshop lifting equipment.

| Model | Load Capacity(t) | Plate Thickness(mm) | Jaw Type | Material | Safety Factor | Surface Treatment | Applicable Equipment |

| CLC-1 | 1 | 3–25 | Vertical | Alloy Steel | 4:1 | Painted/Galvanized | Overhead Crane/Hoist |

| CLC-3 | 3 | 5–40 | Horizontal | Alloy Steel | 4:1 | Powder-Coated | Gantry Crane/Hoist |

| CLC-5 | 5 | 10–60 | Universal | Alloy Steel | 4:1 | Hot-Dip Galvanized | Workshop Crane/Hoist |

| CLC-10 | 10 | 15–100 | Vertical/Horizontal | Alloy Steel | 4:1 | Marine-Grade Coating | Gantry Crane/Overhead Crane |

| CLC-Custom | 1–50+ | Customized | Customized | Alloy/Forged Steel | 4:1+ | Optional Coatings | OEM/Special Cranes |

Lifting steel plates in fabrication workshops

Handling beams,girders,and structural components

Loading/unloading in shipyards,warehouses,and steel mills

Integration with overhead cranes,gantry cranes,and hoists

Industrial projects requiring reliable,high-capacity lifting clamps

Prevents workpiece slippage during lifting

Reduces damage to steel plates or structural beams

Enables safe,repeatable lifting of heavy components

Provides OEM-compliant replacement for existing clamps

Supports diverse lifting requirements across different crane types

Q1:Are these clamps factory-direct or through a distributor?

A1:We are a factory-direct manufacturer providing OEM and custom lifting clamps globally.

Q2:Can you produce custom load capacities or sizes?

A2:Yes.We offer fully customized clamps for different plate thicknesses and lifting requirements.

Q3:Are they safe for repeated heavy-duty use?

A3:Yes.All clamps undergo load testing,quality inspection,and are engineered for long-term industrial use.

Q4:What after-sales support is provided?

A4:Remote installation guidance,video-based operation training,factory video tours,technical assistance,and long-term spare parts supply.

Remote guidance for safe installation and use

Video-based troubleshooting and maintenance support

Factory video tours for verification of product quality

Continuous technical assistance for spare parts and custom adjustments

Long-term supply for wholesale,OEM,and global distributors

1.What is the maximum load capacity?

Available from 1 ton up to 50+tons,with custom designs for higher capacities.

2.Can these clamps handle different steel plate thicknesses?

Yes,vertical,horizontal,and universal types accommodate a wide range of thicknesses.

3.Are these clamps compatible with all crane types?

Yes,they are suitable for overhead cranes,gantry cranes,hoists,and workshop lifting equipment.

4.Is OEM customization available?

Yes,we provide custom sizes,capacities,surface treatments,and markings for global clients.