Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

304 North Cardinal St.

Dorchester Center, MA 02124

If you’ve ever stood on a factory floor and watched a crane lift massive steel coils with millimeter precision, or observed a port gantry smoothly stacking containers in rapid succession, you’ve witnessed the hidden enabler of that motion: the planetary reducer. For decades, our engineering team has dedicated itself to refining this core component, and today, its role is more critical than ever. As a manufacturer at the heart of this technology, we see a clear trend: the shift towards automation and intelligence in material handling isn’t just about software and sensors; it’s fundamentally powered by the physical prowess and precision of advanced transmission systems like our planetary gearboxes.

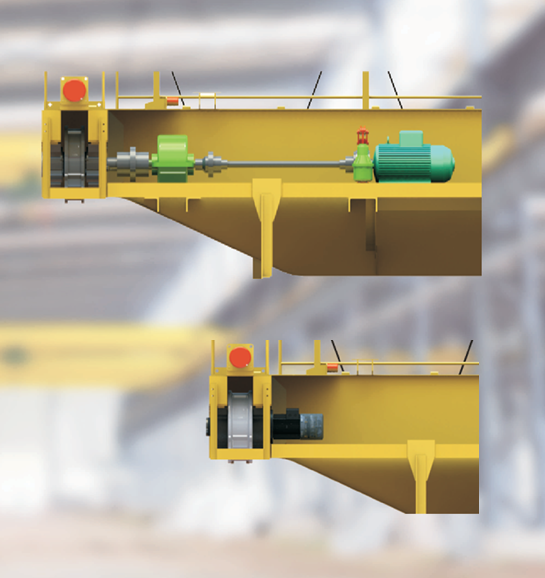

The principle behind our reducers is elegant in its efficiency. By distributing immense torque across multiple planetary gears orbiting a central sun gear, these units deliver exceptional power density. This design directly translates to real-world benefits for crane operators: compact size for easier integration into tight spaces, significantly higher load capacity compared to traditional worm gear reducers, and smoother operation that reduces wear and tear. In demanding applications like steel mill ladle cranes or the high-cycle automated storage and retrieval systems (AS/RS) seen in modern logistics centers, this reliability is not a luxury—it’s an operational necessity. Durability here means less unplanned downtime, a major factor driving predictive maintenance strategies across the industry.

We’re now seeing our technology integrated into some of the most innovative projects. The latest generation of intelligent crane systems for smart warehouses utilize our low-backlash planetary reducers to achieve the precise positioning required for fully automated picking and sorting. In ports, automated stacking cranes (ASCs) rely on their high torque and durability to operate 24/7 with minimal intervention. Perhaps most exciting is their use in renewable energy installation, where our specialized reducers provide the smooth, controlled motion needed to handle delicate but massive wind turbine blades. Each of these applications validates the reducer’s evolution from a simple power transmission part to a key enabler of automation.

The future of planetary reducers is intertwined with the broader Industrial Internet of Things (IIoT). The next step isn’t just about moving loads; it’s about generating actionable data. We’re developing integrated models with sensors that monitor vibration, temperature, and lubrication levels in real-time. This allows operators to move from scheduled maintenance to true predictive maintenance, addressing potential issues before they cause a shutdown. Furthermore, the push for energy efficiency is leading to designs with even higher transmission efficiency, directly lowering the total cost of ownership and supporting sustainable operations.

For businesses considering an upgrade or designing a new automated material handling solution, understanding the transmission system is crucial. The choice of reducer impacts everything from initial system layout and motor sizing to long-term operational costs and reliability. Whether you’re planning a warehouse automation project, upgrading a port crane system, or engineering a custom solution for heavy industrial lifting, the core principles remain: you need strength, precision, and intelligence built into every link of your drive chain.

We understand that navigating these technological choices can be complex. If you’re evaluating how advanced planetary reducer technology can improve the performance, reliability, and intelligence of your lifting or handling equipment, our engineering team is ready to collaborate. We provide more than just components; we offer application expertise and support to help integrate this silent powerhouse into your next project.

To discuss how high-performance planetary gear solutions can be tailored to your specific operational challenges, contact our technical advisory team for a detailed consultation.