Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

304 North Cardinal St.

Dorchester Center, MA 02124

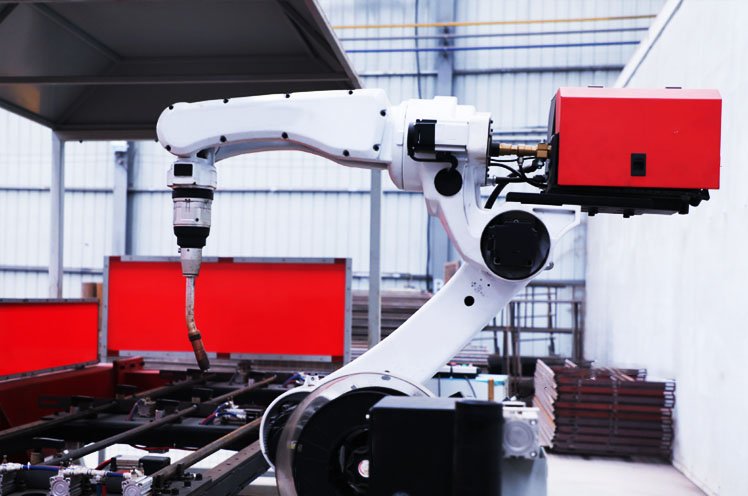

In the heavy industry lifting sector, technological innovation has always been the core driver of safety and efficiency improvements. We deeply integrate advanced electrical control technologies to create a new generation of intelligent control solutions specifically for crane and lifting systems, fundamentally transforming traditional operational methods.

WITS Intelligent Load Scanning Imaging System

Integrated into the main control unit, the WITS area scanning technology utilizes high-precision sensors for real-time imaging and condition analysis of wire ropes on drums. The system continuously monitors rope alignment, tension, and potential damage, triggering early warnings upon detecting risks such as broken wires, abnormal wear, or rope jumping. This not only automates rope load monitoring and wire rope inspection but also elevates crane safety systems to a new level of preventive safety, significantly reducing unexpected downtime and accident risks caused by rope failure.

Glitch-Free™ Adaptive Error Correction Control

To address dynamic load changes during lifting operations, our control system features a unique adaptive error correction algorithm. It analyzes hoist motor operating data and load feedback in real time, making millisecond-level adjustments to lifting and traveling speeds to smoothly counteract load sway. This function effectively eliminates overload risks and load swings caused by operational fluctuations or external factors, ensuring precision lifting and stable load handling. It is particularly suitable for lifting and assembly operations requiring extremely high stability, such as precision equipment handling.

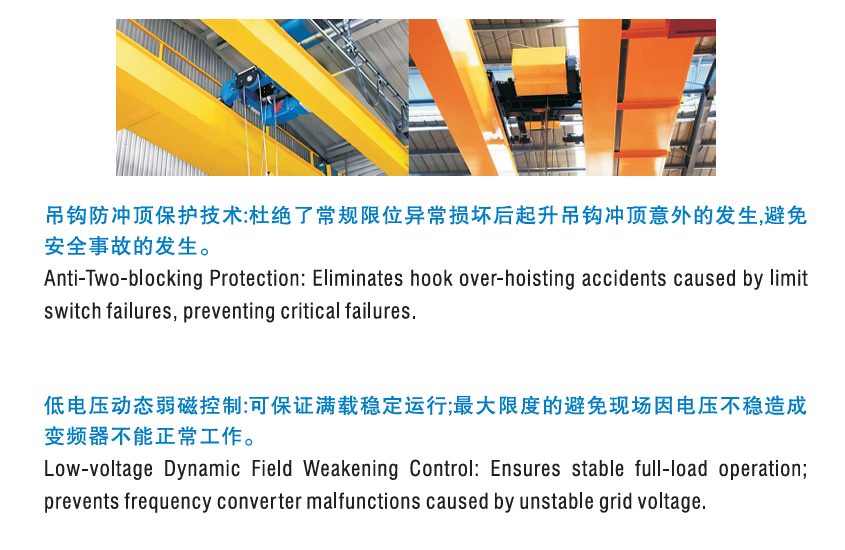

Zero-Failure™ Multi-Redundant Limit Protection

To prevent extreme accidents like “over-hoisting” or “hook dropping” caused by failures of traditional mechanical limit switches, we have developed a multi-redundant protection architecture based on multi-sensor fusion. This system operates independently of the main control loop, utilizing absolute position encoders, visual positioning, and real-time weight data to provide the ultimate safeguard for anti-two block systems and hook height limits. Even if the primary limit fails, the backup system can seamlessly intervene to ensure safe hoisting operations, offering customers a final, robust line of defense for life-critical scenarios.

Low-Voltage Ride-Through (LVRT) Power Assurance Technology

To address common voltage dips or fluctuations in factory power grids, our electrical control system incorporates a low-voltage ride-through function. This technology ensures that cranes maintain stable power supply to critical control circuits and braking systems during momentary low-voltage events in the main grid, preventing frequency converter malfunctions or loss of control. This guarantees crane reliable operation and uninterrupted workflow, significantly enhancing the equipment’s adaptability and crane operational safety in complex grid environments.

From intelligent sensing and real-time error correction to redundant protection and power assurance, our electrical control systems form a complete and reliable intelligent lifting safety ecosystem. Each system shipped undergoes rigorous operational simulation testing to ensure it fulfills its safety promise even in the harshest industrial environments.

As a leading source factory specializing in crane and lifting equipment manufacturing, we integrate these core technologies into our products. We offer comprehensive solutions from design to production. For detailed technical specifications, OEM/ODM inquiries, or to request a quote, please feel free to contact our team.