Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

304 North Cardinal St.

Dorchester Center, MA 02124

Our factory-direct Bridge Launcher is engineered for the efficient and precise placement of large bridge segments, offering exceptional reliability and performance in demanding construction environments. Designed for bridge construction projects, heavy lifting, and material handling, this equipment ensures smooth, controlled movements while placing beams and segments at great heights. It includes detailed mechanical drawings to facilitate seamless installation and integration. Ideal for highway and railway bridge construction, it effectively addresses challenges such as large-scale load handling, height precision, and time-efficient construction processes. We offer a full after-sales guarantee, and each production order is closely tracked by a dedicated specialist, ensuring transparent monitoring, timely delivery, and dependable support from factory to site.

As a direct crane manufacturer,the Bridge Launcher is designed for bridge construction sites,infrastructure projects,

and heavy structural installations.Built for precision,stability,and high lifting capacity,it enables safe and efficient placement of bridge segments,

beams,and girders.Our Factory-direct production ensures durable components,reliable performance,and cost-effective solutions for construction projects worldwide.

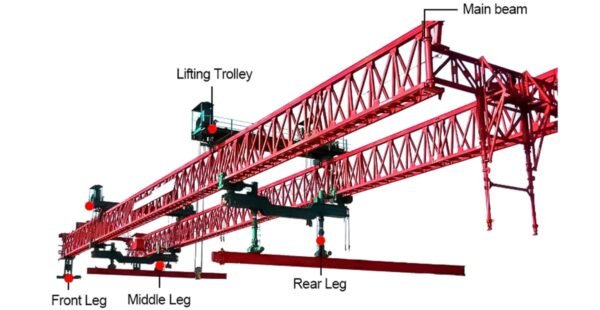

The Bridge Launcher features a robust frame and adjustable support system to handle large spans and heavy loads,

providing controlled movement of bridge sections from fabrication to final placement

Product Overview

The Bridge Launcher is a specialized equipment solution designed for the installation of precast concrete beams across highways,railways,

and large-span bridge projects.Built with a high-strength truss structure and advanced control systems,it ensures precise beam placement,

stable operation,and efficient construction progress.As a source manufacturer,we provide customizable bridge launchers suitable for various span lengths,

beam weights,and complex working conditions.

Heavy-Duty Lifting Capacity

Designed for safe handling of large bridge segments and girders.

Adjustable Support System

Allows precise positioning over varying terrains and construction conditions.

Factory-direct Quality&Durability

High-strength steel construction,precision welding,and corrosion-resistant coating.

Efficient Movement&Placement

Smooth operation enables controlled launching and placement of bridge components.

Safety&Reliability

Built-in stabilization systems and robust design minimize operational risks.

| Model | Lifting Capacity(t) | Span(m) | Segment Length(m) | Launching Height(m) | Travel Speed(m/min) | Hoist Type | Power Supply |

| BL100 | 100 | 20–50 | 10–30 | 5–20 | 5–10 | Wire rope/Electric hoist | 380–660V/50Hz |

| BL200 | 200 | 30–70 | 15–40 | 8–25 | 3–8 | Wire rope/Electric hoist | 380–660V/50Hz |

Bridge construction and installation

Infrastructure and highway projects

Heavy beam and girder placement

Large-scale civil engineering projects

Precise placement of heavy bridge segments

Efficient launching over large spans

Safe handling in challenging construction terrains

Reducing manual labor and improving operational speed

Handling large-scale infrastructure projects with stability

Q1:What advantages come with a Factory-direct crane?

A1:Direct manufacturing ensures high-quality materials,precise assembly,and cost efficiency.

Q2:Can the Bridge Launcher be customized?

A2:Yes,lifting capacity,span,segment length,and travel speed can all be tailored.

Q3:Is it suitable for global bridge construction projects?

A3:Yes,designed for European,Asian,Middle Eastern,and American construction standards.

Q4:What support is available for installation and operation?

A4:Remote guidance,video tutorials,and engineering consultation are provided.

Remote technical guidance and setup support

Video-assisted maintenance and troubleshooting

Factory video demonstrations for operational training

Continuous engineering support for hoist and structural adjustments

Long-term consultation for optimized bridge launching operations

Q1:What is the maximum lifting capacity?

A1:Up to 200 tons depending on model.

Q2:Can it be used on uneven terrain?

A2:Yes,adjustable supports allow operation on varying site conditions.

Q3:What is the maximum segment length it can handle?

A3:Up to 40 meters depending on the model.

Q4:Can the crane be customized for different bridge types?

A4:Yes,span,lifting height,and segment handling can be adapted.

Q5:Is operator training provided?

A5:Yes,through video tutorials and remote guidance.