Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

304 North Cardinal St.

Dorchester Center, MA 02124

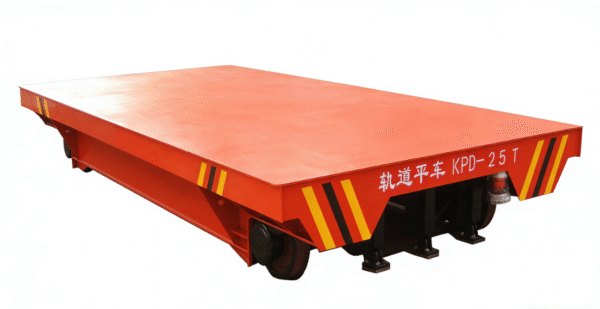

As a factory-direct manufacturer specializing in industrial transfer equipment,our KPD Electric Transfer Cart is designed for efficient,safe,and precise transport of heavy materials in workshops,steel plants,foundries,and warehouses.With a reinforced steel frame,high-performance electric motors,and advanced control systems,the KPD cart ensures stable movement for coils,billets,molds,heavy machinery,and structural components.

The cart is available in both rail-guided and free-running configurations,providing flexibility for various workshop layouts and production workflows.Global buyers searching for factory-direct electric transfer carts,OEM heavy-duty transport vehicles,customized industrial transfer carts,and intelligent material handling solutions will find the KPD model highly suitable.

Robust and Stable Structure:Reinforced steel chassis ensures high-load stability.

Customizable Load Capacity:Ranges from 5 to 500 tons according to operational needs.

Flexible Travel Options:Rail-guided or free-running designs to suit workshop environments.

Advanced Control System:Pendant,remote control,and PLC automation for precise operation.

Durable Components:Industrial-grade materials designed for long-term,high-frequency use.

Factory-Direct Customization:Platform size,wheel type,travel type,speed,and power supply can be tailored.

There are two power supply modes for KPD-type low-voltage electric flat cars: three-phase and single-phase. The single-phase model is suitable for small-tonnage vehicles (under 50 tons). Its key advantage is that it eliminates one conductive rail, significantly cutting down the investment cost.

The working principle of the KPD three-phase low-voltage electric flat car is as follows: The three-phase 380V power supply is stepped down to 36V by a fixed ground-based step-down control cabinet and fed into the track. It is then transferred to the on-board step-up transformer via the flat car’s conductive device, converted back to 380V, and used to power the motor via the control system.

The working principle of the KPD single-phase low-voltage electric flat car is as follows: The two-phase 380V power supply is stepped down to 36V by a fixed ground-based step-down control cabinet and fed into the track. It is then transferred to the on-board rectifier via the flat car’s conductive device, rectified to 45V DC, and used to drive the DC motor via the control system.

| Model | Capacity(t) | Travel Type | Speed(m/min) | Platform Size(mm) | Power Supply | Control Mode |

| KPD-5 | 5 | Rail/Free | 0–30 | Custom | Cable Reel/Drag Chain | Pendant/Remote |

| KPD-10 | 10 | Rail/Free | 0–25 | Custom | Cable Reel/Drag Chain | Pendant/Remote |

| KPD-20 | 20 | Rail/Free | 0–20 | Custom | Cable Reel/Drag Chain | Pendant/PLC |

| KPD-Custom | Custom | Custom | Custom | Custom | Custom | Custom Intelligent System |

Transport of steel coils,billets,and slabs

Mold and die transfer in workshops

Interbay material movement in industrial plants

Heavy machinery relocation

Automated production line material flow

Warehouse logistics and internal transport

Safely and efficiently moves heavy and oversized materials

Reduces reliance on forklifts and manual handling

Enables multi-station and long-distance material transfer

Supports high-frequency production and logistics workflows

Integrates seamlessly with automated factory systems for intelligent operations

Factory-direct manufacturing with deep expertise in industrial transfer equipment

Heavy-duty structural design for high-load and continuous operation

OEM and custom options for capacity,platform size,travel type,and control system

Reliable electric drive and control technology for smooth and safe operation

Global support network for spare parts,technical guidance,and distributor collaboration

Remote online guidance for installation,operation,and troubleshooting

Video-based maintenance and setup instructions

Factory video tours for quality confirmation

Continuous assistance for adjustments,upgrades,and part replacement

Long-term supply of OEM components and electrical modules

1.Can this cart operate on both rails and free-running modes?

Yes,it can be configured for rail-guided or free-running operation depending on workshop layout.

2.What load capacities are available?

From 5 to 500 tons,customizable according to operational requirements.

3.Is remote or automated control available?

Yes,pendant control,remote control,and PLC automation are all supported.

4.Can the platform size and wheel type be customized?

Yes,OEM customization is available for all critical specifications.

5.Can this cart be integrated into automated production lines?

Yes,it can work seamlessly with intelligent factory systems for automated material handling.

Differences of K-Series Electric Transfer Carts:

KPX Electric Transfer Cart:Light to medium load,cost-effective,flexible for short-distance transport

KPJ Electric Transfer Cart:Heavy load,high-frequency,suitable for long-distance multi-station transport

KPT Electric Transfer Cart:Heavy load,highly customizable,ideal for workshops and automated production lines

KPD Electric Transfer Cart:Heavy load,high-frequency,compatible with intelligent factories,highly stable

| Model | Load Capacity(t) | Travel Type | Control Options | Typical Applications | Key Features |

| KPX | 2–500 | Rail/Free | Pendant/Remote/PLC | Short-distance workshop transport,mold&steel transfer,warehouse logistics | Flexible,cost-effective,suitable for light to medium loads |

| KPJ | 5–500 | Rail/Free | Pendant/Remote/PLC | Multi-station,long-distance transport,heavy material handling | High-load stability,designed for high-frequency multi-station operations |

| KPT | 5–500 | Rail/Free | Pendant/Remote/PLC | Workshop handling,automated production lines | Highly customizable,adjustable platform size and travel options |

| KPD | 5–500 | Rail/Free | Pendant/Remote/PLC | Steel plants,heavy-duty handling,intelligent factories | High stability,compatible with automated production lines,suitable for high-frequency operation |